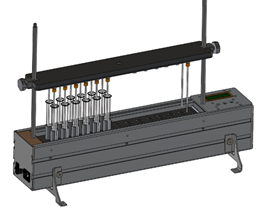

The ECTS 10_1 evaporative concentrator is designed for removing (evaporating) solvents from samples by a directed gas (air) flow with the possibility of simultaneously heating the samples to a set temperature. The evaporative concentrator allows up to 24 samples to be concentrated simultaneously.

The evaporative concentrator is a monoblock structure consisting of one functional module-a temperature-controlled unit with a controller and a control panel. The thermostatic unit structurally includes a solid-state heating module and a gas distribution cover.

The gas flow directed from the gas distribution cap through the capillaries enters the sample container and accelerates the evaporation process due to the directed entrainment of molecules from the solvent surface. By adjusting the gas flow rate and heating temperature of the sample container, you can achieve optimal performance during the evaporation process.

A stable temperature in the container (vial or test tube) is maintained by thermostating a solid – state element-a bed with heaters installed inside and cylindrical inserts that provide improved heat transfer and reliable fixation of the container.

The temperature of the temperature-controlled module can be set in the range from (room temperature + 10°C) to +99.9 °C and is regulated by the controller.

When working with the evaporative concentrator, it is possible to use both air and inert gases (nitrogen, helium, argon) as a gas. An inert gas is necessary in the case of evaporation of samples whose target components are sensitive to oxidation by air oxygen.

The gas flow rate is set using the handle of the pressure microregulator located on the gas distribution cover. Intensity (linear velocity) the flow rate is also determined by the internal diameter of the capillary.

The evaporative concentrator allows evaporation in three different ways.

- Evaporation of the solvent only by heating the sample.

- Evaporation of the solvent in a gas stream without heating the sample.

- Evaporation of the solvent in a gas stream with simultaneous heating of the sample.

Thus, it is possible to choose the optimal concentration mode, in which the solvent will be quickly removed without boiling the sample and destroying the target substances.

The use of capillaries of the same length and diameter makes it possible to provide reproducible evaporation conditions for homogeneous samples. The kit includes capillaries of two internal diameters (they are consumable). The capillary with a large diameter (1.59 mm) is designed for evaporation of large (up to 30 cm3) volumes of solvent. If it is necessary to evaporate volumes less than 1.5 cm3, a capillary with a smaller internal diameter of 0.75 mm should be used.

| Maximum gas inlet pressure, bar | 2 |

| Maximum number of sample containers to be installed | 2 x 12 seats* |

| Maximum diameter of the sample container, mm | 25 |

| Type of gas distribution cap retainer | spring-loaded presser |

| Gas inlet line (inner x outer diameter), mm | 4 x 6 |

| Type of pressure microregulator | manual, no pressure relief |

| External diameters of blow-off capillaries | 1/8”, 1/16” |

| Material of blow-off capillaries | teflon, SS316 |

| Operating temperature range, °C | from room + 10.0 to +99.9 |

| Accuracy of maintaining the temperature in the operating range, °C | ± 0,1 |

| Time to enter the mode, min, max | 20 |

| Housing material of the thermostatic unit | D16T |

| Power supply, V/Hz | 220/50 |

| Power consumption, W | 350 |

| Overall dimensions, mm | 465 x 190 x 605 |

| Weight, kg, max | 5,2 |

* The delivery package includes:

1 module for cylindrical tubes with 12 seats;

1 module for Eppendorf tubes 1.5 cm3 with 12 seats.

Separately supplied:

plate for 8 ml vials for 12 vials;

inserts for 1.5 ml vials, put instead of vklydyshey under the test tube.